TYPE OF SCREWS

SINGLE SCREW

Basic application, screw is devided to the 3 zones

Kinds of single screws for extrusion:

- 3 zones standard screw

- Barrier screws

- Multiple thread screw

Application:

- Pipe profile

- Film

- Compound

- Recycling

- Sheet

- Blow molding

- Wire

- Tyre

- Alimentary

PARALEL TWIN SCREW (CO-ROTATING TWIN SCREW)

Each screw spin in the same direction and consist of the several parts on the shaft (the design depends on the type of application).

Screws can consist of the separate elements (with different design) and all of them are installed on the shaft one by one.

Application:

- Pipe

- Profile

- Compound

- Recycling

- Sheet

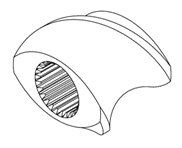

CONICAL TWIN SCREW (CO-ROTATING TWIN SCREW)

Each screw spin in the same direction. Also this kind of screw can be produces like a modular (several screw elements on the shaft). The design depends on the type of application.

Application:

- Pipes

- Profiles (PVC, W-PVC)

COUNTER ROTATING TWIN SCREW

There are two types of counter-rotating extruders – parallel twin screw extruder and conical twin screw extruder.

A parallel twin screw has a consistent barrel diameter through the entire barrel.

A conical twin screw extruder has a taper shape. Both counter rotating machines with often have barrel venting.

The barrels and screws of these machines are not modular so they may need to be changed for your specific application.

Properties:

-

Each screw spin in the opposite direction and the design depends on the type of application.

-

This kind of machine has lower rpm and generally has smaller L/D ration.

-

The screw direction allows for less shear force than a single or co-rotating machine.

Application: